Ngwakọta ihe niile jikọtara ya na eriri na-eme ka ọ dị ike na ihe plastik.Ọrụ nke resin na ihe ndị mejupụtara dị oke mkpa.Nhọrọ nke resin na-ekpebi usoro nke usoro njirimara njirimara, ụfọdụ ihe eji arụ ọrụ na arụ ọrụ (ihe ọkụ ọkụ, ọkụ ọkụ, nguzogide gburugburu ebe obibi, wdg), Njirimara resin bụkwa isi ihe na-aghọta n'ibu akụrụngwa nke ihe mejupụtara.Mgbe ahọpụtara resin, windo nke na-ekpebi oke nke usoro na akụrụngwa nke ihe mejupụtara na-akpaghị aka.Thermosetting resin bụ ụdị resin a na-ejikarị eme ihe maka ihe mejupụtara resin matrix n'ihi nrụpụta ya dị mma.Thermoset resins fọrọ nke nta ka ọ bụrụ naanị mmiri mmiri ma ọ bụ nke siri ike na ụlọ okpomọkụ, ma n'echiche ha, ha dị ka monomers nke mebere resin thermoplastic karịa resin thermoplastic na steeti ikpeazụ.Tupu a gwọọ resins thermosetting, enwere ike ịhazi ya ka ọ bụrụ ụdị dị iche iche, ma ozugbo a gwọchara ya site na iji ndị na-agwọ ọrịa, ndị na-ebido ma ọ bụ okpomọkụ, a pụghị ịkpụzi ha ọzọ n'ihi na a na-emepụta njikọ kemịkalụ n'oge ọgwụgwọ, na-eme ka obere ụmụ irighiri ihe na-agbanwe ka ọ bụrụ njikọ ụzọ atọ. polymers siri ike nke nwere oke molekụla dị elu.

E nwere ọtụtụ ụdị resin thermosetting, nke a na-ejikarị bụ resin phenolic,epoxy resins, bis-ịnyịnya resins, vinyl resins, phenolic resins, wdg.

(1) Resin phenolic bụ resin mbụ nke thermosetting nwere ezigbo mmachi, ezigbo nguzogide okpomọkụ na ihe dielectric mgbe a gwọchara ya, na njirimara ya pụtara ìhè bụ ezigbo ihe na-egbochi ire ọkụ, ọnụego ntọhapụ ọkụ dị ala, obere anwụrụ ọkụ, na combustion.Gas nke ewepụtara adịchaghị egbu egbu.Usoro nhazi ahụ dị mma, enwere ike ịmepụta ihe mejupụtara ihe mejupụtara ya site na ịkpụzi, winding, ntinye aka, ịgbasa, na usoro pultrusion.A na-eji ọnụ ọgụgụ dị ukwuu nke ihe mejupụtara resin dabeere na phenolic eme ihe n'ime ime ihe ịchọ mma nke ụgbọ elu obodo.

(2)Epoxy resinbụ matriks resin mbụ ejiri n'arụ ụgbọ elu.A na-eji ihe dị iche iche mara ya.Ndị na-agwọ ọrịa dị iche iche na ndị na-eme ngwa ngwa nwere ike nweta ọnọdụ okpomọkụ dị iche iche site na ụlọ okpomọkụ ruo 180 ℃;ọ nwere elu n'ibu Njirimara;Ezi eriri dabara ụdị;okpomọkụ na iru mmiri na-eguzogide;ezigbo ike;ezigbo nrụpụta (ezigbo mkpuchi, viscosity resin na-agafeghị oke, mmiri dị mma, bandwit nrụgide, wdg);adabara n'ozuzu co-curing ịkpụzi nke nnukwu components;ọnụ ala.Usoro ịkpụzi nke ọma na ịdị ike pụtara ìhè nke resin epoxy na-eme ka ọ nọrọ n'ọnọdụ dị mkpa na resin matrix nke ihe mejupụtara ihe mejupụtara.

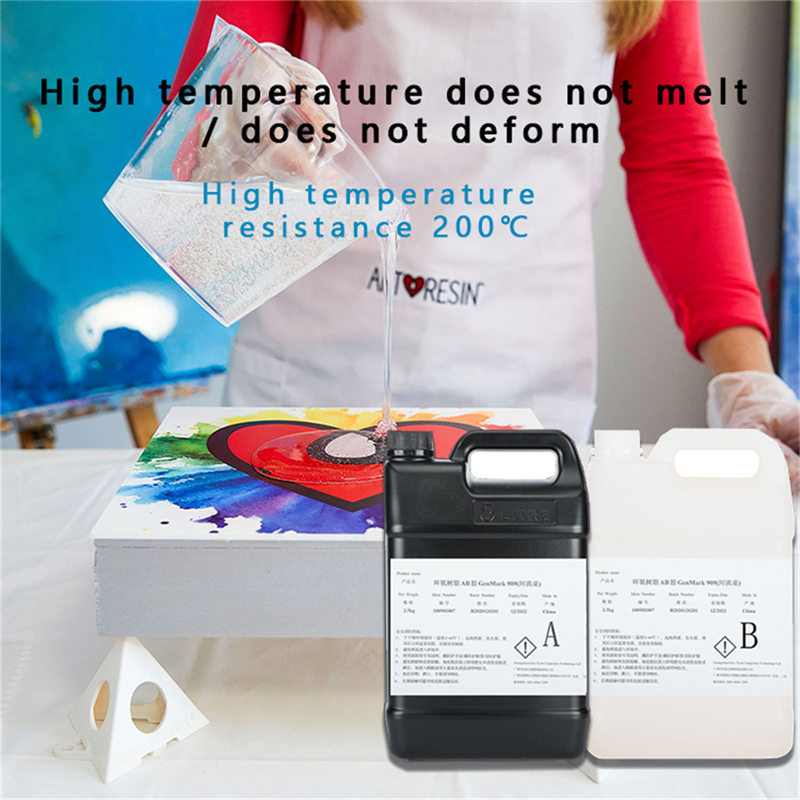

(3)Vinyl resina ghọtara dị ka otu n'ime ezigbo resin na-eguzogide corrosion.Ọ nwere ike iguzogide ọtụtụ acid, alkalis, ngwọta nnu na mgbasa ozi mgbaze siri ike.A na-eji ya eme ihe n'ọtụtụ akwụkwọ, ụlọ ọrụ kemịkalụ, ngwá electronic, mmanụ ala, nchekwa na njem, nchebe gburugburu ebe obibi, ụgbọ mmiri, Ụlọ ọrụ ọkụ ọkụ.Ọ nwere njiri mara nke polyester unsaturated na epoxy resin, nke mere na ọ nwere ma ihe nrụpụta ọrụ dị mma nke resin epoxy yana arụmọrụ usoro dị mma nke polyester unsaturated.Na mgbakwunye na nguzogide corrosion pụtara ìhè, ụdị resin a nwekwara ezigbo nguzogide okpomọkụ.Ọ na-agụnye ụdị ọkọlọtọ, ụdị okpomọkụ dị elu, ụdị ọkụ ọkụ, ụdị nkwụsị mmetụta na ụdị ndị ọzọ.Ngwa nke resin vinyl n'ime rọba siri ike (FRP) dabere na ntinye aka, ọkachasị na ngwa mgbochi corrosion.Site na mmepe nke SMC, ngwa ya na nke a bụkwa ihe a na-ahụ anya.

(4) A na-emepụta resin bismaleimide gbanwetụrụ (nke a na-akpọ bismaleimide resin) iji mezuo ihe achọrọ nke ụgbọ elu ọgụ ọhụrụ maka matrix resin composite.Ndị a chọrọ na-agụnye: nnukwu components na mgbagwoju profaịlụ na 130 ℃ Mepụta nke components, wdg Tụnyere na epoxy resin, Shuangma resin bụ tumadi ji elu iru mmiri na okpomọkụ na-eguzogide na elu ọrụ okpomọkụ;mwepu bụ na nrụpụta adịghị mma dị ka epoxy resin, na ọgwụgwọ okpomọkụ dị elu (na-agwọta n'elu 185 ℃), na-achọ okpomọkụ nke 200 ℃.Ma ọ bụ ruo ogologo oge na okpomọkụ n'elu 200 ℃.

(5) Cyanide (qing diacoustic) ester resin nwere ala dielectric mgbe nile (2.8 ~ 3.2) na kemgwucha obere dielectric ọnwụ tangent (0.002 ~ 0.008), elu iko mgbanwe okpomọkụ (240 ~ 290 ℃), Low shrinkage, obere mmiri absorption, magburu onwe ya. n'ibu Njirimara na bonding Njirimara, wdg, na o nwere yiri nhazi technology ka epoxy resin.

Ka ọ dị ugbu a, a na-eji resins cyanate eme ihe n'akụkụ atọ: bọọdụ sekit a na-ebipụta maka ngwa ngwa dijitalụ na nke dị elu, ihe nrụpụta ihe na-ebufe ebili mmiri na-arụ ọrụ dị elu na ihe nhazi ihe mejupụtara maka ikuku.

N'ikwu ya n'ụzọ dị mfe, epoxy resin, arụmọrụ nke resin epoxy abụghị nanị ihe jikọrọ ya na ọnọdụ njikọ, kamakwa na-adabere n'ụdị molekụla.Otu glycidyl dị na resin epoxy bụ akụkụ na-agbanwe agbanwe, nke nwere ike ibelata viscosity nke resin ma melite arụmọrụ usoro, ma n'otu oge ahụ na-ebelata okpomọkụ nke resin a gwọrọ.Ụzọ kachasị mma iji meziwanye ihe ọkụ na akụrụngwa nke resin epoxy gwọrọ bụ ịdị arọ molekụla dị ala yana multifunctionalization iji bulie njupụta crosslink na iwebata ihe owuwu siri ike.N'ezie, iwebata ihe owuwu siri ike na-eduga na mbelata nke solubility na mmụba nke viscosity, nke na-eduga n'ịbelata arụmọrụ resin epoxy.Otu esi emeziwanye nguzogide okpomọkụ nke sistemu resin epoxy bụ akụkụ dị oke mkpa.Site n'echiche nke resin na onye na-agwọ ọrịa, otu ndị na-arụ ọrụ na-arụ ọrụ, na-abawanye njupụta crosslinking.Nke kachasị elu nke Tg.Ọrụ a kapịrị ọnụ: Jiri resin epoxy multifunctional ma ọ bụ onye na-agwọ ọrịa, jiri resin epoxy dị ọcha dị elu.Usoro a na-ejikarị eme ihe bụ ịgbakwunye o-methyl acetaldehyde epoxy resin n'ime usoro ọgwụgwọ, nke nwere mmetụta dị mma na ọnụ ala.Ka ọ̀tụ̀tụ̀ ịdị arọ molekụla na-ebuwanye ibu, ka nkesa ịdị arọ molekụla na-adị warara karị, na-adịkwa elu Tg.Ọrụ a kapịrị ọnụ: Jiri resin epoxy multifunctional ma ọ bụ onye na-agwọ ọrịa ma ọ bụ ụzọ ndị ọzọ nwere nkesa ịdị arọ molekụla dịtụ otu.

Dị ka akwa resin matrix na-arụ ọrụ dị ka ihe mejupụtara ihe mejupụtara ya, ihe ndị dị iche iche ya, dị ka usoro nhazi, ihe ndị na-ekpo ọkụ na ihe ndị na-emepụta ihe, ga-egbo mkpa nke ngwa bara uru.nrụpụta matrix resin gụnyere solubility na ihe mgbaze, gbazee viscosity (mmiri) na mgbanwe viscosity, na oge gel na-agbanwe na okpomọkụ (window usoro).Ngwakọta nke resin formulation na nhọrọ nke mmeghachi omume okpomọkụ na-ekpebi mmeghachi omume kemịkalụ kinetics (ọnụọgụ ọgwụgwọ), Njirimara rheological chemical (viscosity-okpomọkụ na oge), na mmeghachi omume thermodynamics (exothermic).Usoro dị iche iche nwere ihe dị iche iche chọrọ maka viscosity resin.N'ikwu okwu n'ozuzu, maka usoro ikuku, viscosity resin na-adịkarị gburugburu 500cPs;maka usoro pultrusion, viscosity resin dị gburugburu 800 ~ 1200cPs;maka usoro mmeghe oghere, viscosity resin na-adịkarị gburugburu 300cPs, na usoro RTM nwere ike ịdị elu, mana N'ozuzu, ọ gaghị agafe 800cPs;maka prepreg usoro, a chọrọ viscosity dịtụ elu, n'ozuzu gburugburu 30000 ~ 50000cPs.N'ezie, ihe ndị a chọrọ viscosity metụtara njirimara nke usoro, akụrụngwa na ihe n'onwe ha, ma ọ bụghị static.N'ikwu okwu n'ozuzu, ka okpomọkụ na-abawanye, viscosity nke resin na-ebelata na oke okpomọkụ dị ala;Otú ọ dị, ka okpomọkụ na-abawanye, mmeghachi omume ọgwụgwọ nke resin na-agakwa n'ihu, na-ekwu okwu kinetically, okpomọkụ The mmeghachi omume ọnụego okpukpu abụọ maka ọ bụla 10 ℃ abawanye, na nke a approximation ka bara uru maka atụmatụ mgbe viscosity nke reactive resin usoro na-abawanye na a. ụfọdụ ihe dị egwu viscosity.Dịka ọmụmaatụ, ọ na-ewe nkeji 50 maka sistemu resin nke nwere viscosity nke 200cP na 100 ℃ iji mee ka viscosity ya ruo 1000cP, mgbe ahụ, oge achọrọ maka sistemụ resin ahụ iji bulie viscosity mbụ ya site na ihe na-erughị 200cPs ruo 1000cPs na 110℃. ihe dị ka nkeji iri abụọ na ise.Nhọrọ nke usoro usoro kwesịrị ịtụle viscosity na oge gel.Dịka ọmụmaatụ, n'ime usoro mmeghe oghere, ọ dị mkpa iji hụ na viscosity na okpomọkụ na-arụ ọrụ dị n'ime oke viscosity nke usoro ahụ chọrọ, na ndụ ite nke resin na okpomọkụ a ga-adị ogologo oge iji hụ na resin. enwere ike ibubata.Iji chịkọta ọnụ, nhọrọ nke ụdị resin na usoro injection ga-atụle isi ihe gel, oge na-ejuputa na okpomọkụ nke ihe.Usoro ndị ọzọ nwere ọnọdụ yiri nke ahụ.

N'ime usoro ịkpụzi, nha na ọdịdị nke akụkụ (ebu), ụdị nkwado, na usoro usoro na-ekpebi ọnụego mbufe ọkụ na oke nnyefe nke usoro.Resin na-agwọ okpomọkụ nke na-ekpo ọkụ, nke a na-emepụta site na nhazi nke njikọ kemịkal.Ka njikọ kemịkalụ na-etolite kwa otu olu kwa nkeji oge, ka a na-ewepụtakwu ike.Ọnụ ọgụgụ mbufe okpomọkụ nke resins na polymers ha na-adịkarị ala.Ọnụ ọgụgụ nke iwepụ okpomọkụ n'oge polymerization enweghị ike dakọtara ọnụ ọgụgụ nke ọgbọ okpomọkụ.Okpomọkụ ndị a na-abawanye na-eme ka mmeghachi omume kemịkal na-aga n'ihu n'ọsọ ọsọ ọsọ, na-eme ka mmeghachi omume nke onwe ya pụta ga-emecha mee ka nrụgide nrụgide ma ọ bụ mmebi nke akụkụ ahụ pụta.Nke a bụ ihe a ma ama n'ịmepụta akụkụ ndị mejupụtara nnukwu ọkpụkpụ, ma ọ dị mkpa karịsịa ịkwalite ụzọ usoro ọgwụgwọ.Nsogbu nke mpaghara "okpomọkụ na-ekpo ọkụ" na-akpata site na ọnụ ọgụgụ dị elu nke exothermic nke prepreg na-agwọ ọrịa, na ọdịiche dị na steeti (dị ka ọdịiche okpomọkụ) n'etiti windo usoro ụwa na windo usoro mpaghara bụ n'ihi otu esi ejikwa usoro ọgwụgwọ."Okpomọkụ n'otu n'otu" na akụkụ (karịsịa na ọkpụrụkpụ ntụziaka nke akụkụ), iji nweta "okpomọkụ edo edo" dabere na nhazi (ma ọ bụ ngwa) nke ụfọdụ "teknụzụ unit" na "usoro mmepụta ihe".Maka akụkụ ndị dị mkpa, ebe ọ bụ na a ga-agbanye nnukwu okpomọkụ na gburugburu ebe obibi, okpomọkụ na-ebili nwayọọ nwayọọ, na mgbe ụfọdụ akụkụ ahụ agaghị agwọta ya kpamkpam.N'oge a, ọ dị mkpa ka a na-etinye ọkụ inyeaka iji mezue mmeghachi omume na-agafe agafe, ya bụ, ikpo ọkụ na-aga n'ihu.

Nkà na ụzụ na-emepụta ihe na-emepụta ihe na-abụghị autoclave na-adabere na nkà na ụzụ ịmepụta autoclave omenala.N'ikwu ya n'ụzọ sara mbara, usoro ọ bụla mejupụtara ihe mejupụtara nke na-adịghị eji akụrụngwa autoclave nwere ike ịkpọ teknụzụ na-emepụta ihe na-abụghị autoclave..Ka ọ dị ugbu a, ngwa nke teknụzụ na-akpụzi ihe na-abụghị autoclave na mpaghara ikuku na-agụnye ntụzịaka ndị a: teknụzụ na-abụghị autoclave prepreg, teknụzụ na-akpụzi mmiri, teknụzụ na-akpụzi prepreg, teknụzụ na-agwọ ọrịa microwave, teknụzụ na-agwọ elektrọn, teknụzụ na-akpụ akpụ akpụ akpụ. .N'ime teknụzụ ndị a, OoA (Outof Autoclave) teknụzụ prepreg dị nso na usoro nhazi autoclave ọdịnala, ma nwee ọtụtụ ntinye akwụkwọ ntuziaka na ịtọ ntọala ntọala akpaaka, yabụ a na-ewere ya dị ka akwa anaghị kpara akpa nke nwere ike imezu. na nnukwu ọnụ ọgụgụ.Teknụzụ na-emepụta Autoclave.Otu ihe dị mkpa mere eji eji autoclave maka akụkụ ndị mejupụtara akụkụ dị elu na-arụ ọrụ bụ iji nye nrụgide zuru oke na prepreg, karịa ikuku ikuku nke gas ọ bụla n'oge a na-agwọ ọrịa, iji gbochie nhazi nke pores, na nke a bụ OoA prepreg Isi ihe isi ike na nkà na ụzụ. kwesịrị imebi.Ma enwere ike ịchịkwa porosity nke akụkụ ahụ n'okpuru nrụgide agụụ na arụmọrụ ya nwere ike iru arụmọrụ nke autoclave gwọrọ laminate bụ ihe dị mkpa maka nyochaa ogo OoA prepreg na usoro ịkpụzi ya.

Mmepe nke teknụzụ prepreg OoA sitere na mmepe resin.Enwere isi ihe atọ na mmepe nke resins maka OoA prepregs: otu bụ ịchịkwa porosity nke akụkụ ndị a kpụrụ akpụ, dị ka iji mgbakwunye mmeghachi omume-gwọrọ resins iji belata volatiles na ọgwụgwọ ọgwụgwọ;nke abụọ bụ imeziwanye arụmọrụ nke resin a gwọrọ iji nweta ihe ndị na-emepụta resin nke usoro autoclave mepụtara, gụnyere ihe ndị na-ekpo ọkụ na ihe ndị na-arụ ọrụ;nke atọ bụ iji hụ na prepreg nwere ezigbo nrụpụta, dị ka ijide n'aka na resin nwere ike ịgbanye n'okpuru nrụgide gradient nke ikuku ikuku, na-ahụ na ọ nwere ogologo ndụ viscosity na okpomọkụ zuru oke ụlọ n'èzí oge, wdg. Ndị na-emepụta ihe na-emepụta ihe na-eduzi. nchọpụta ihe onwunwe na mmepe dị ka ihe chọrọ imewe na usoro usoro.Ntuziaka ndị bụ isi kwesịrị ịgụnye: imeziwanye ihe eji arụ ọrụ, ịba ụba oge mpụga, ibelata ọgwụgwọ okpomọkụ, na imeziwanye mmiri na nguzogide okpomọkụ.Ụfọdụ n'ime nkwalite arụmọrụ ndị a na-emegiderịta onwe ha., dị ka elu ike na obere okpomọkụ ọgwụgwọ.Ịkwesịrị ịchọta ebe nguzozi ma tụlee ya nke ọma!

Na mgbakwunye na mmepe resin, usoro nrụpụta nke prepreg na-akwalite mmepe ngwa nke OoA prepreg.Ọmụmụ ihe ahụ chọpụtara mkpa ọwa prepreg vacuum channels maka ime laminates zero-porosity.Nnyocha ndị sochirinụ egosila na prepregs nke ọkara impregnated nwere ike imeziwanye ikike ikuku gas nke ọma.A na-eji resin mee ka OoA prepregs ọkara, a na-ejikwa eriri kpọrọ nkụ dị ka ọwa maka ikuku ikuku.Gases na volatiles na-etinye aka na ọgwụgwọ nke akụkụ ahụ nwere ike ịpụpụ site na ọwa ndị dị otú ahụ na porosity nke akụkụ ikpeazụ bụ <1%.

Usoro akpa akpa oghere bụ nke usoro na-abụghị autoclave forming (OoA).Na nkenke, ọ bụ usoro ịkpụzi nke na-emechi ngwaahịa ahụ n'etiti ihe ebu na akpa oghere, ma na-eme ka ngwaahịa ahụ sie ike site na ịmegharị ihe iji mee ka ngwaahịa ahụ dịkwuo kọmpat na mma arụ ọrụ.Isi n'ichepụta usoro bụ

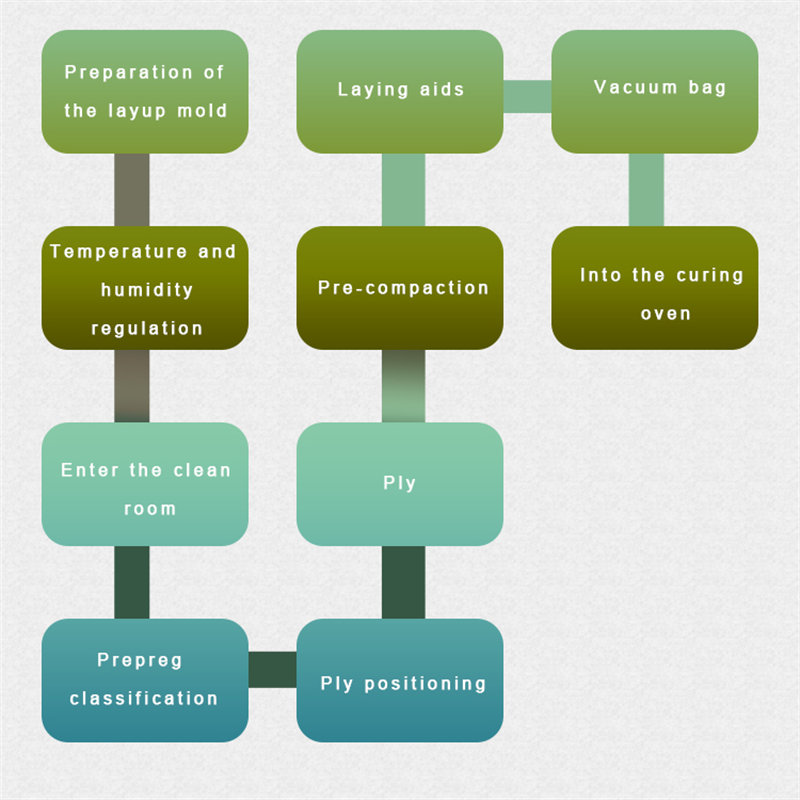

Nke mbụ, a na-etinye ihe ntọhapụ ma ọ bụ akwa ntọhapụ n'elu ebu (ma ọ bụ mpempe iko).A na-enyocha prepreg dị ka ọkọlọtọ nke prepreg ejiri mee ihe, ọkachasị gụnyere njupụta elu, ọdịnaya resin, ihe na-agbanwe agbanwe na ozi ndị ọzọ nke prepreg.Bee ihe prepreg ka ọ bụrụ nha.Mgbe ị na-egbutu, ṅaa ntị na ntụziaka nke eriri.N'ozuzu, a chọrọ ngbanwe ntụziaka nke eriri ndị ahụ ka ọ bụrụ ihe na-erughị 1 Celsius.Tinye nọmba oghere ọ bụla wee dekọọ nọmba prepreg.Mgbe ị na-edobe akwa akwa, a ga-edobe akwa ahụ n'ụzọ siri ike dabere n'usoro nhazi nke achọrọ na mpempe akwụkwọ ndenye, na ihe nkiri PE ma ọ bụ akwụkwọ ntọhapụ kwesịrị jikọọ n'akụkụ ntụziaka nke eriri, na ikuku ikuku kwesịrị ijikọ. a ga-achụpụ ya na ntụziaka nke eriri.Ihe nkedo na-agbasa prepreg ma kpochapụ ya dị ka o kwere mee iji wepụ ikuku n'etiti ọkwa.Mgbe ị na-edobe, ọ na-adị mkpa mgbe ụfọdụ ịkwanye prepregs, nke a ga-agbanye n'akụkụ eriri eriri.N'ime usoro nkesa ahụ, a ga-enweta nchikota na ntanye ntanye, na akwa akwa nke oyi akwa ọ bụla kwesịrị ịkwanye.N'ozuzu, splicing oghere nke unidirectional prepreg bụ ndị a.1mm;The braided prepreg na-ekwe ka ọ machie, ọ bụghị splicing, na overlaod obosara bụ 10 ~ 15mm.Na-esote, ṅaa ntị na vacuum pre-compaction, na ọkpụrụkpụ nke mgbapụta mgbapụta dịgasị iche dị ka ihe dị iche iche chọrọ.Ebumnuche bụ ịkwanye ikuku nke tọrọ na layup na volatiles na prepreg iji hụ na ịdị mma nke akụkụ ahụ dị n'ime.Mgbe ahụ, a na-edobe ihe inyeaka na akpa oghere.Akara akpa na ịgwọ ọrịa: Ihe ikpeazụ achọrọ bụ enweghị ike ịwụpụ ikuku.Rịba ama: Ebe a na-enwekarị ntapu ikuku bụ nkwonkwo sealant.

Anyị na-emepụtakwafiberglass kpọmkwem roving,ihe eji eme fiberglass, fiberglass ntupu, nafiberglass kpara akpa.

Kpọtụrụ anyị :

Nọmba ekwentị:+8615823184699

Nọmba ekwentị: +8602367853804

Email:marketing@frp-cqdj.com

Oge nzipu: Mee-23-2022